1

1

At present, a wide range of domestic and foreign flue gas desulfurization methods, mainly divided into dry (or semi-dry) and wet two categories. Most of the wet flue gas desulfurization process uses alkaline slurry or solution as absorbent, the technology is relatively mature, is currently the most widely used flue gas desulfurization technology, according to the different types of absorbent can be divided into limestone - gypsum method (calcium method) (SNCR), selective catalytic reduction (SCR); flue gas desulphurization and denitrification integrated process of the emergence of the cause of the formation of flue gas denitrification technology is the most common use of non-catalytic reduction (SNCR) The desulfurization and denitrification technology can achieve desulfurization and denitrification in the same system, with the advantages of compact equipment, small footprint, less investment in infrastructure, convenient management and low production cost.

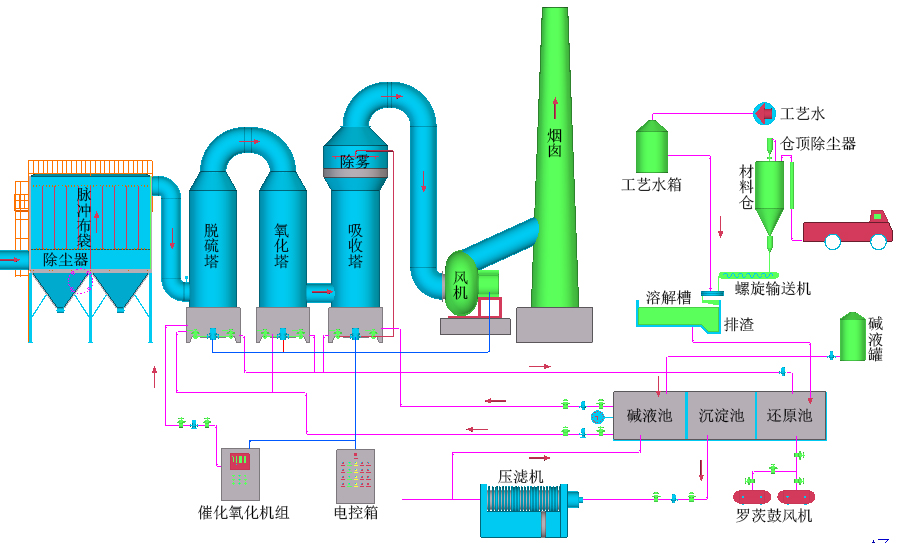

First, the process profile:

At present, a wide range of domestic and foreign flue gas desulfurization methods, mainly divided into dry (or semi-dry) and wet two categories. Most of the wet flue gas desulfurization process uses alkaline slurry or solution as absorbent, the technology is relatively mature, is currently the most widely used flue gas desulfurization technology, according to the different types of absorbent can be divided into limestone - gypsum method (calcium method) (SNCR), selective catalytic reduction (SCR); flue gas desulphurization and denitrification integrated process of the emergence of the cause of the formation of flue gas denitrification technology is the most common use of non-catalytic reduction (SNCR) The desulfurization and denitrification technology can achieve desulfurization and denitrification in the same system, with the advantages of compact equipment, small footprint, less investment in infrastructure, convenient management and low production cost.

Our company's flue gas desulfurization and denitrification integration process mainly by the composite catalytic oxidation process and lye absorption process composition, and the traditional wet desulfurization + SCR / SNCR process compared to the low investment and high efficiency. The complete set of equipment used in the system integrates the principles of aerodynamics, fluid mechanics, thermodynamics, aerosol mechanics and chemical reaction. The oxidation tower uses self-atomization unit body, the absorption tower uses the spray combination to carry on the omni-directional, the entire covering highly effective purification absorption. The whole system has the characteristics of wide operating elasticity, large load range, small system resistance, large gas-liquid contact area, fast absorption speed, high purification efficiency, simultaneous desulfurization and denitration.

Basic structure:

1) oxidation tower: divided into the intake chamber, three multi-unit atomization throat, three multi-unit vortex plate, dehydration board and the main steel structure.

2) absorption tower: divided into the upper part of the defogging area, the middle of the spray area and the lower part of the slurry area and the main three main steel structure.

3) supporting system: access to air duct, automatic dosing system, integrated circulation pool, electrical control system.

Second, the process characteristics:

1, the project investment and operating costs less to optimize the process to achieve the greatest social and environmental benefits;

2, the system equipment compact, small footprint, simple and practical, easy maintenance and management;

3, forced oxidation and crystallization occurs mainly in the oxidation replacement pool, to prevent the tower internal surface scaling, plug the problem;

4, compared with the traditional process, denitrification process for low-temperature flue gas, practical and strong;

5, the operation and management is simple, no hidden safety problems;

Third, the process description:

The flue gas first enters the oxidation tower to oxidize the NO into high solubility NO2 and N2O3, and then enter the absorption tower, using sodium hydroxide as the absorbent to remove the nitrogen oxides NOx and SO2 in the flue gas, Sodium hydroxide replacement agent out of recycling. (flow chart)

Fourth, the implementation of emissions standards (GB13271-2014):

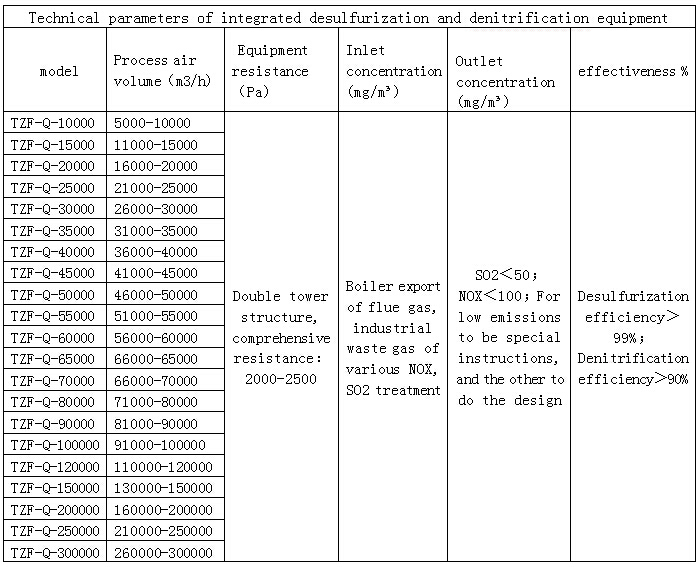

Fifth, the equipment parameters:

版权所有·北京天中方环保科技有限公司 京ICP备14001063号-2