1

1

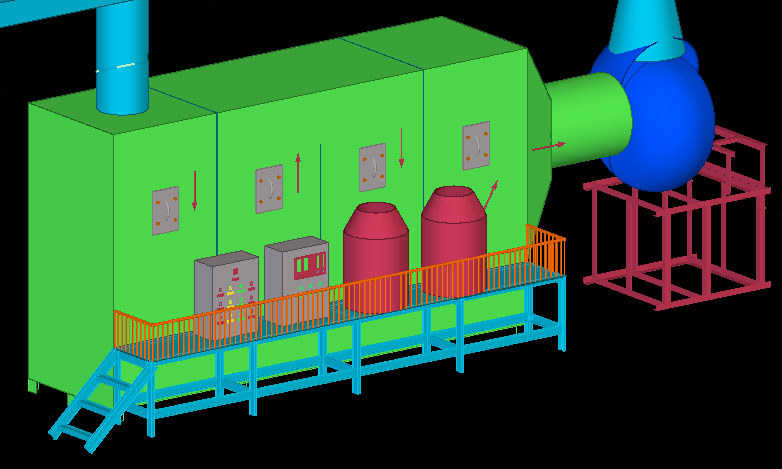

The exhaust gas is firstly collected by the absorption port and adjusted to the optimal flow rate by the flow regulating valve. The adjusted exhaust gas is collected by the branch pipe from the branch pipe to the supervisor and then enters the exhaust gas purification unit for catalytic oxidation and is highly oxidized under the action of the catalyst. The reaction principle is at room temperature and pressure, and the oxidant electron coupling, resulting in a more stable hydroxyl radicals or peroxide radicals. These free radicals have very strong oxidizing properties and can react with the organic compounds in the exhaust gas. The organic radicals generated by the reaction can continue to participate in the chain reaction. Will not be absorbed by the chemical absorption of organic gases in the exhaust gas decomposition of unsaturated hydrocarbons, hydrocarbon unsaturated hydrocarbons in the rapid oxidation of H2O and CO2, so as to achieve the purpose of the exhaust gas purification. This process runs low cost, no clogging, long-term stable operation, safe and reliable.

First, the composite catalytic oxidation of exhaust gas purification equipment Overview:

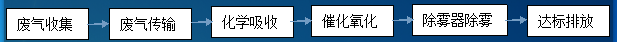

Principle of the process: The exhaust gas collected after the first branch into the main pipeline after the collection, and then sent by the total pipeline into the exhaust gas purification unit, the exhaust gas purification unit in the exhaust gas purification, waste gas treatment device for the horizontal tower, divided into four work Chamber, the first studio for the chemical degradation device (acid-base neutralization), the chemical reaction of the exhaust gas absorption of the exhaust gas treatment device, the second, three working chamber is the catalytic oxidation device. Decomposition of the organic gas which can not be completely absorbed by the front stage and has an off-flavor, or the decomposition of a gaseous substance which has not been subjected to a purification treatment in the chemical treatment. In the tower, the gas from top to bottom through the first studio, the absorption of liquid absorption to remove some of the absorption of liquid and can absorb the liquid and the reaction of harmful gases, and by washing to remove some small dust. And then into the follow-up catalytic oxidation device so that the moisture content in the allowable range of the exhaust gas in the oxidation device by the catalytic oxidant decomposition into hydroxides and carbon oxides, from the bottom to the reverse mist spray through the multi-layer mist After scrubbing, the gas continues to move forward into the filtration filter chamber (fourth chamber). After the chemical treatment, the moisture remaining in the exhaust gas can be removed by the demister, and the purified gas equipment Export into the induced draft fan, into the exhaust pipe discharge standards at high altitude, do not let any harmful gases into the atmosphere. In the case of the lower part of the spray-type absorption liquid treatment device, a certain amount of absorbent is added according to the needs of the case so that the pH value of the solution reaches about 9, and has strong ability of washing absorption and neutralization, This absorption capacity, to achieve the purpose of continuous purification of exhaust gas, after the spray absorption of liquid filtration and oxidation decomposition, the gas discharge standards. Purification rate of more than 90%. Waste gas collection and treatment process block diagram is as follows:

Second, the advantages:

1, can efficiently remove volatile organic compounds VOCs, sulfur dioxide, hydrogen sulfide, nitrogen oxides, non-methane total hydrocarbons, ammonia, benzene, toluene, xylene, formaldehyde, acetone, butanone, indole, nitro, sulfur Ether, mercaptans, phenols and other major pollutants, as well as a variety of odor, deodorization efficiency of up to 99% or more, deodorant effect greatly exceeded the national 1993 enactment of the stench pollutant discharge standards (GB14554-93) and 1996 Year "issued by the" Air Pollutant Comprehensive Emission Standard "(GB16297-1996).

2, low operating costs, low operating costs of treatment chemicals, long-term operation will not block the phenomenon does not rebound.

3, adaptable: adapt to a variety of high concentrations, the amount of the atmosphere, different industrial VOCs volatile organic compounds, inorganic substances and malodorous gases, purification efficiency, continuous 24-hour operation, safe and reliable operation.

4, a high degree of automation: the entire exhaust gas treatment system using PLC automatic control to achieve remote control and monitoring.

Third, use:

This product is widely used in the oil industry, chemical plants, printing plants, paper mills, coking plants, sewage treatment plants, waste treatment plants, sludge drying plants, pharmaceutical plants, food processing plants, recycled rubber plants, rubber products factory, plastic Products factory, tire factory, galvanizing plant, metal products factory, paint factory, fertilizer plant, fertilizer plant, furniture factory, and all harmful and toxic gas emissions applications.

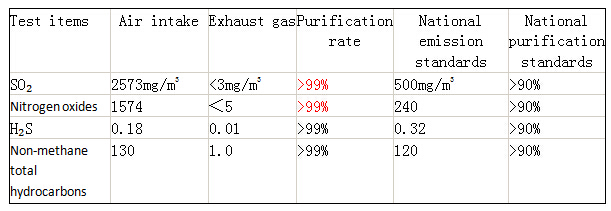

Fourth, the exhaust gas detection comparison table:

The equipment through the Beijing Municipal Environmental Protection Bureau authority certification testing, testing reports recognized by international and domestic authorities, fully meet the state requirements of the emission standards.

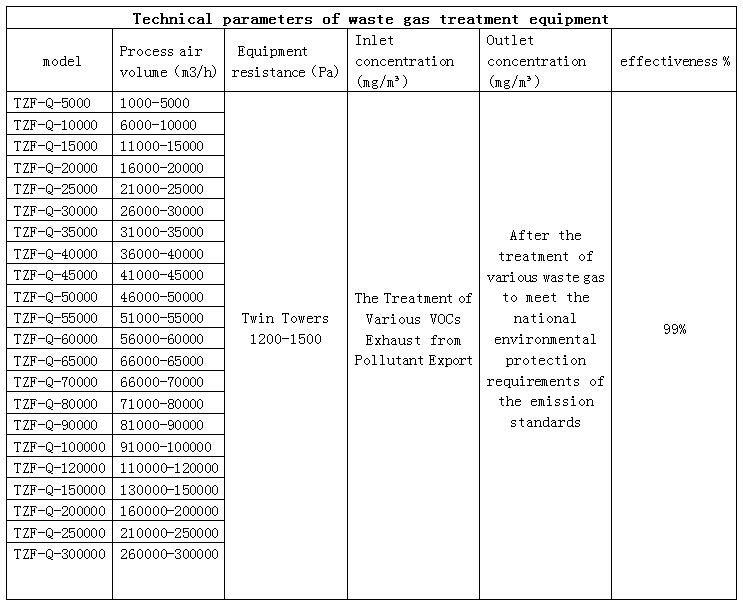

Fifth, the equipment parameters:

版权所有·北京天中方环保科技有限公司 京ICP备14001063号-2