1

1

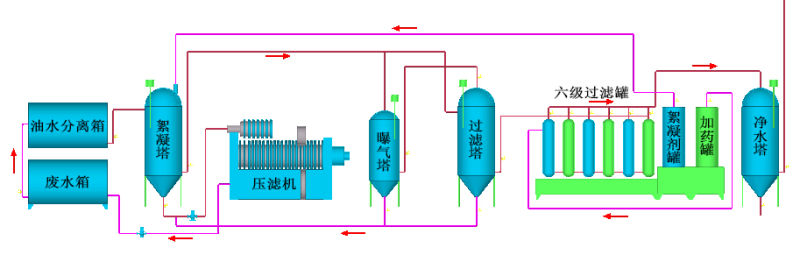

The waste water is firstly discharged into the waste water tank and then separated by the oil-water separator. The separated sewage is filtered through the filter. Since the raw water contains a large amount of suspended pollutants, it needs to be removed first, and then enters the follow-up process after the sewage filter. And then the waste water is sent into the three-stage catalytic oxidation treatment tank to realize the decomposition and removal of the organic pollutants in the catalytic oxidation tank so that the COD index of the effluent reaches the discharge standard and can be partially oxidized to remove the ammonia nitrogen index; After the ammonia nitrogen content of waste water is still very high, there is a large ammonia, the need to adjust the PH value of alkali to 10-11, and then use ammonia removal of ammonia nitrogen for separation, after the above process, will be fully discharged Of the waste water drainage tank to prepare for recycling.

First, the process description:

The waste water is firstly discharged into the waste water tank and then separated by the oil-water separator. The separated sewage is filtered through the filter. Since the raw water contains a large amount of suspended pollutants, it needs to be removed first, and then enters the follow-up process after the sewage filter. And then the waste water is sent into the three-stage catalytic oxidation treatment tank to realize the decomposition and removal of the organic pollutants in the catalytic oxidation tank so that the COD index of the effluent reaches the discharge standard and can be partially oxidized to remove the ammonia nitrogen index; After the ammonia nitrogen content of waste water is still very high, there is a large ammonia, the need to adjust the PH value of alkali to 10-11, and then use ammonia removal of ammonia nitrogen for separation, after the above process, will be fully discharged Of the waste water drainage tank to prepare for recycling.

Industrial waste water treatment equipment:

Second, equipment advantages

Catalytic oxidation has the following advantages:

(1) the use of highly efficient catalyst to improve the oxidation efficiency, efficient catalyst can be oxidant dosage and COD ratio from 10: 1 to 0.5: 1, greatly reducing operating costs.

(2) has a strong decolorizing function, the petrochemical, printing and dyeing, chemical, paper and other industries decolorization of sewage has a very good effect.

(3) Oxidant preparation is simple, low investment and operating costs, and other treatment methods compared to the cost of relatively low.

(4) the degradation of organic compounds to generate oxygen-containing small molecules mainly compounds, does not produce secondary pollutants, and in reducing the COD while increasing the BOD5 / COD value for the follow-up to create the conditions for biochemical treatment.

(5) The biggest advantage of the process can be attached to any of the traditional treatment process, so the original high-concentration wastewater treatment process with other processes can not match the unique advantages.

Sewage treatment project

Third, the scope of application

Applicable to municipal, power, pharmaceutical, chemical, rubber, tires, electroplating, metallurgy, medical,

Machinery, paper, printing, food processing, aquaculture and other industries

Domestic water treatment equipment

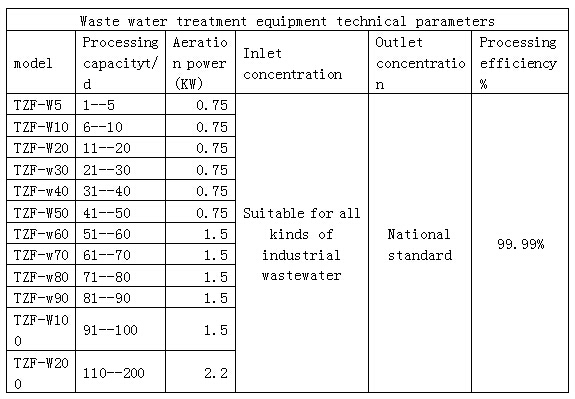

Fourth, equipment parameters

Pure water treatment equipment

版权所有·北京天中方环保科技有限公司 京ICP备14001063号-2