1

1

The air purifying method of the pulse bag filter is an external filter type, and the dust-laden gas enters the filtering room of each unit through the air duct and flows through the device in the hopper. The airflow is distributed through appropriate diversion and natural flow, The dust in the dust-laden gas is directly separated into the ash bucket after the natural sedimentation, and the rest of the dust is guided by the diversion system and enters the middle box filtration area with the airflow and is absorbed outside the filter bag surface. Filtration of clean gas through the bag through the box, through the off-line butterfly valve from the exhaust pipe.

Pulse dust removal equipment

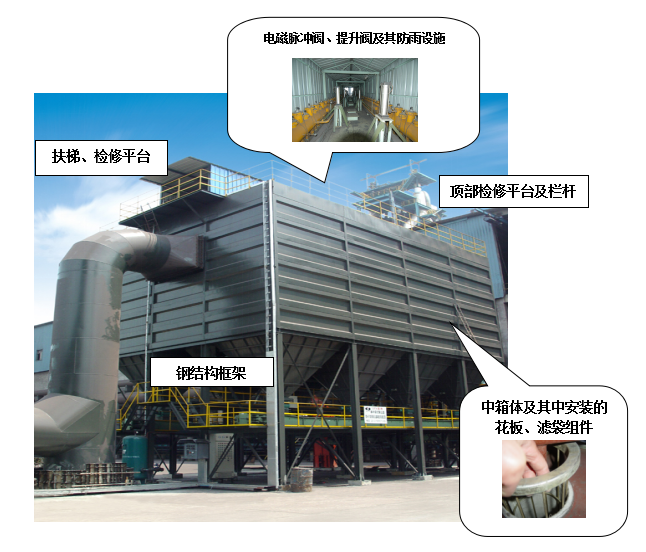

System equipment diagram:

First, the working principle

The air purifying method of the pulse bag filter is an external filter type, and the dust-laden gas enters the filtering room of each unit through the air duct and flows through the device in the hopper. The airflow is distributed through appropriate diversion and natural flow, The dust in the dust-laden gas is directly separated into the ash bucket after the natural sedimentation, and the rest of the dust is guided by the diversion system and enters the middle box filtration area with the airflow and is absorbed outside the filter bag surface. Filtration of clean gas through the bag through the box, through the off-line butterfly valve from the exhaust pipe.

Filter bag with compressed air for injection cleaning, cleaning mechanism by the air bag, electromagnetic pulse control valve and other components. Purge, the pulse valve is opened, the compressed gas through the jet nozzle to the bag, and its surrounding with the injection of gas into the filter bag inside, causing the filter bag full jitter and the formation of the back-blowing from the inside out of the role of air, The outer surface of the filter bag dust, to achieve the purpose of cleaning.

Dust falling into the hopper is discharged through the dump valve. Dusters with advanced off-line butterfly valve, with off-line cleaning function and offline maintenance. Resistance is small, air flow. Dust control (including cleaning control, etc.) using PLC control. All overhaul and maintenance work is carried out in the clean room of the dust remover and outside of the machine, without entering the interior of the dust remover.

Second, the composition:

1. Body: It consists of the upper box, the box, into the air channel, hopper components, access doors, brackets and other components. For the ontology, we design the load combination to strength design; using Q235 pressure plate production.

2. Dust collection, filtration system: mainly by the filter bag, bag cage, flower plate components, distribution system components.

3. Injection cleaning, unloading ash system: mainly by the gas bag, electromagnetic pulse valve, off-line valve, ash discharge valve and other components.

4. Electric control system: Mainly by the PLC control cabinet, dust collector site control box.

5. Platform, railings, ladder and hand (gas) valve repair platform

Dust collector top rain protection device ---- used to protect the top of the electromagnetic pulse valve dust collector facilities.

6. Compressed air system: including compressors, compressed air pipes, pressure gauges, air handling triple pieces.

Third, the main structural features of equipment:

1, hopper diversion device: to solve the phenomenon of uneven air intake, the centrifugal sedimentation of the flue gas play a role, not directly washed bags. To ensure that the filter bag life.

2, the use of electromagnetic pulse valve technology: low pressure, high efficiency, long life diaphragm electromagnetic pulse valve, coupled with unique design and injection pipe blowing means, so that the bag filter cleaning method has been completely changed.

3, the top of the bag with a spring ring up the form, sealing performance, changing bags fast.

4, the cage with cold-drawn steel wire, the surface do anti-corrosion treatment, to avoid the dust collector work for some time after the cage surface rust and filter bag bonding to ensure the smooth bag, while reducing the process of bag bag damage.

5, The dust collector adopts the lift-top cover, drainage facilities, and the escalator platform.The facilities are designed with humanized concept to protect the top device of the dust catcher and facilitate the personnel to overhaul, use and manage.

6, dust box, roof, ash bucket outlet of the reliable sealing joints to prevent the air mixture.

7, low-pressure injection technology: low pressure, high efficiency, long life diaphragm electromagnetic pulse valve application, coupled with unique design and processing of blowing means, so that the bag filter cleaning method has been completely changed.

Fourth, the system features:

1, set the flue gas flow system, separation of large particles of dust, the bag filter play a protective role. To prevent particles washed cloth bag, which will help improve the life of the bag.

2, the top of the dust collector dust, antifreeze, protect the cylinder, solenoid valve, pulse valve from rain, dust, and extend the service life; antifreeze protection to ensure the normal use of pneumatic components in the cold winter.

3, the flange connection and the top of the reliable dust seal, reducing system air leakage.

4, the system PLC control, high degree of automation, cleaning, dust removal, security, all the screen display. Simple operation, convenient control, stable and reliable.

5, dust collector structure and location for the site conditions, pipeline layout does not affect the production operation.

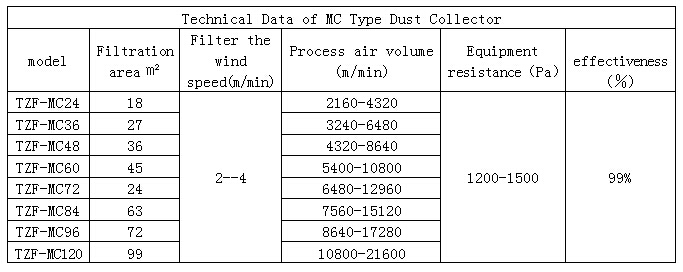

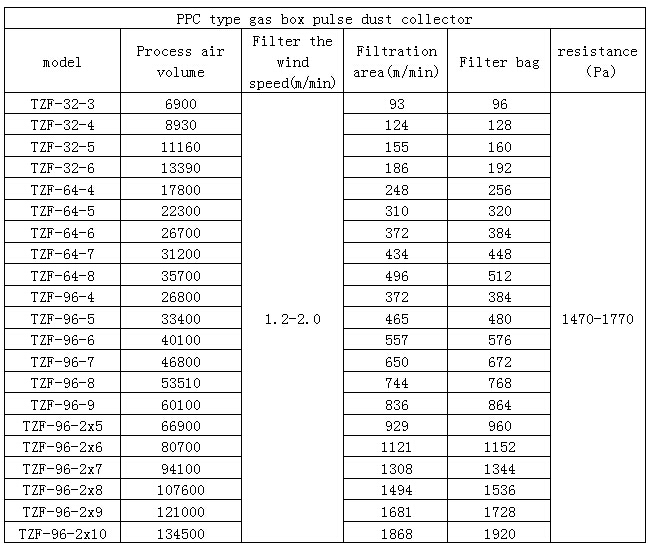

Fifth, equipment parameter table:

版权所有·北京天中方环保科技有限公司 京ICP备14001063号-2