1

1

First, the chemical composition of waste gas:

In the chemical industry, the production facilities are complex and the treatment facilities are different. The treatment of waste gas plays an important role in the petrochemical industry. Chemical waste gas has the following characteristics:

1, flammable, explosive gas more. Such as low-boiling ketone, aldehyde, easily polymerized unsaturated hydrocarbons, etc., a large number of flammable, explosive gas without taking appropriate measures, easily lead to fire, explosion, great harm.

2, most of the emissions are irritating or corrosive. Such as sulfur dioxide, nitrogen oxides, chlorine, hydrogen fluoride and other gases are irritating or corrosive, in particular, the largest sulfur dioxide emissions, sulfur dioxide gas directly damage human health, corrosion of metals, buildings and sculpture on the surface, but also easily oxidized into sulfate Land, polluted soil, forests, rivers, lakes.

3, exhaust particles in the floating species, and great harm. Chemical production of the exclusion of floating particles, including dust, smoke, acid mist, a wide range of environmental hazards. Especially when the floating particles and harmful gases exist simultaneously can produce synergies, more serious harm to people.

Second, the coking plant emissions components:

The main pollutants are benzene, aromatic hydrocarbons, aliphatic hydrocarbons, alkanes, phenols, H2S, naphthalene dust, ammonia and asphalt smoke, the pollutants are high concentrations of toxic and flammable and explosive gases.

Third, the refinery gas composition:

Main pollutants: volatile organic compounds (VOC), hydrocarbons, organic sulfides such as thiol sulfide, phenol, aromatic, low concentrations of inorganic sulfide hydrogen sulfide, ammonia, biochemical aeration oxygen, sewage Oxygen release gas, the decomposition of sludge released coke air-cooled open air-cooled distribution of stench, coking furnace combustion gas produced by non-desulfurization and other stench.

Fourth, coal tar pitch gas composition:

Coal tar pitch is a by-product of coking, i.e. a black substance remaining in the distillation kettle after distillation of the tar. It is only the physical properties of refined tar are different, there is no clear boundaries, the general method of division is to provide softening point of 26.7 ℃ (cubic method) for the following tar, 26.7 ℃ above the pitch. Coal tar pitch mainly contains hardly volatile anthracene, phenanthrene, pyrene, and so on. These substances are toxic, and the properties of the coal tar pitch are different due to the different contents of these components. Temperature changes on the impact of coal tar pitch is very big, easy to brittle in winter, easy to soften in summer. Heating a special odor; heated to 260 ° C in 5 hours later, which contains anthracene, phenanthrene, pyrene, and other components will be volatile out.

Second, the oil asphalt: Petroleum asphalt is crude oil distillation residue. According to the degree of refining, at room temperature into a liquid, semi-solid or solid. Petroleum asphalt black and shiny, with a high temperature. Because it was in the production process has been distilled to more than 400 ℃, which contains little volatile components, but there may still be a polymer of volatile hydrocarbons, these substances are more or less harmful to human health.

Chemical industry flammable, explosive gases are more, most of the emissions are irritating or corrosive, VOCs emissions control first consider the safety issues, and then according to the concentration of exhaust gas content analysis to determine the treatment program.

Hebei Province to the case of coal coking plant design solutions:

1, coking plant waste gas analysis

Benzene hydrocarbons, aromatic hydrocarbons: usually refers to molecules containing benzene ring structure of hydrocarbons, most of the gas at room temperature for the liquid, boiling point: ≥ 80 ℃

Aliphatic hydrocarbons: hydrocarbons with basic properties of aliphatic compounds are called aliphatic hydrocarbons. At room temperature for the gas.

Alkane: that is saturated saturated hydrocarbon group (saturated group), is a hydrocarbon saturated hydrocarbon, its overall structure mostly only by carbon, hydrogen, carbon carbon single bond and hydrocarbon single bond, but also the most simple one Organic compounds. At room temperature with the increase in the number of carbon atoms sub-gas, liquid, solid, melting point does not exceed 100 ℃.

Phenol: hydroxyl (-OH) and aromatic nucleus (benzene ring or thick benzene ring) directly connected to the formation of organic compounds, most of the phenol colorless needle crystal or white crystals, a small number of alkylphenol high boiling liquid.

H2S: Under normal conditions is a flammable acid gas, colorless, low concentrations of rotten eggs smell, there are highly toxic. The flash point is <-50 ° C, the melting point is -85.5 ° C, the boiling point is -60.4 ° C.

Naphthalene: an organic compound, white, volatile and has a special smell of polycyclic hydrocarbon crystals. The temperature of 80.5 ° C, the boiling point of 217.9 ° C, at room temperature for solid.

Ammonia: nitrogen and hydrogen compounds, boiling point -33.5 ℃, at room temperature for the gas.

Asphalt: Asphalt is composed of different molecular weight hydrocarbons and non-metallic derivatives of dark brown complex mixture, is a high viscosity organic liquid, a liquid, the surface was black, boiling point <470 ℃.

2、Brief introduction of process route

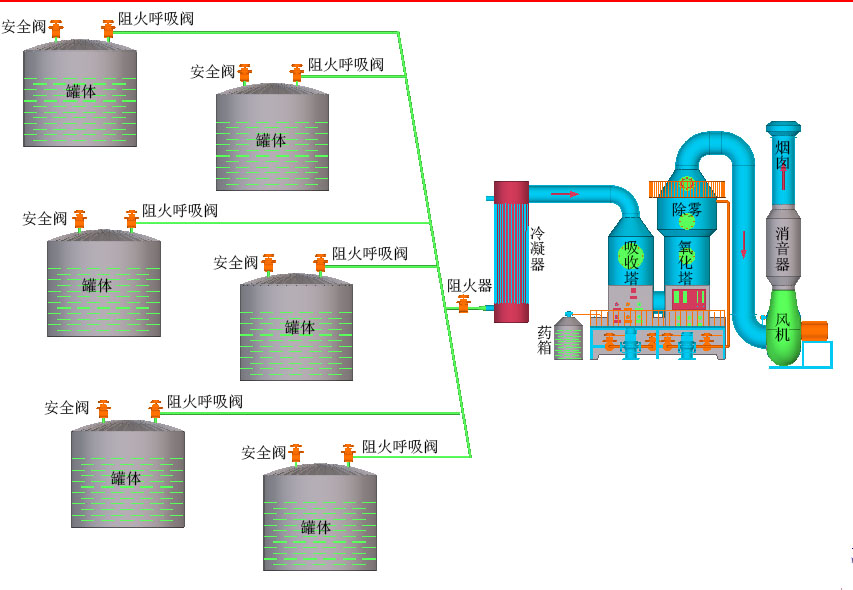

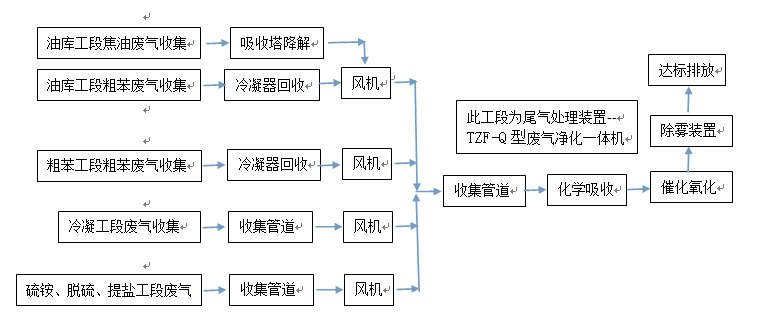

According to the exhaust gas composition analysis, the phenol, naphthalene and bituminous smoke in the exhaust gas are almost solid at normal temperature and crude liquid at normal temperature, and most of the remaining exhaust gas is gaseous. According to the nature of the exhaust gas, the single component organic matter is collected into the absorption degradation system. The condensate and the solid compound drips to the corresponding condensate storage tank, the recycling, the non-condensed waste gas and the non-absorbed degrading waste gas are collected in a unified way, and the storage tank with the vent port is exhausted, The exhaust gas purifying machine (absorbing and purifying system + catalytic oxidation system) of TZF-Q series exhaust gas purifying machine (the absorption purification system + the catalytic oxidation system) is introduced into the exhaust gas purifying system of TZF-Q series which is made by our company. Can make the enterprise exhaust emission standards, collection system perspective is as follows:

3, waste gas collection and processing process is as follows:

4, process principle

The

principle of composite catalytic oxidation: the use of the

corresponding chemical absorption solution for the chemical absorption

of harmful gases degradation, mixed contact reaction, and then with the

catalyst oxidant collisions, so that it into harmless substances.

In the role of the catalyst for efficient oxidation. The

reaction principle is that under normal temperature and pressure, the

organic harmful exhaust gas is coupled with the oxidant electronically,

thereby forming the more stable hydroxyl radical or the peroxide free

radical. These free radicals have very strong

oxidizing properties and can react with the organic compounds in the

exhaust gas. The organic radicals generated by the reaction can continue

to participate in the chain reaction. Will not be

absorbed by the chemical absorption of organic gases in the exhaust gas

decomposition of unsaturated hydrocarbons, hydrocarbon unsaturated

hydrocarbons in the rapid oxidation of H2O and CO2, so as to achieve the

purpose of the exhaust gas purification. This process does

not add any adsorption material, mainly using three kinds of chemical

agents, two kinds of strong oxidizing gas, using the principle of

compound catalytic oxidation of the biggest bright spot is running low

cost, no clogging, long-term stable, safe and reliable.

5, process design features

(1) The process of chemical degradation, catalytic oxidation technology, do not add any adsorbate, will not block the phenomenon of rebound can be achieved long-term stable operation of equipment, safe and reliable.

(2) purification efficiency, the complete removal of organic compounds in the exhaust gas and compound odor, the key is the emission of gas odor-free, to ensure discharge standards, see design indicators.

(3) absorption of liquid recycling, low operating costs, system equipment, compact, small footprint, simple and practical, easy maintenance and management.

(4) The entire set of equipment can be fully automated PLC control, the scene without someone to operate, easy to manage.

(5) can be set on-line gas detection, remote monitoring, keep abreast of the various stages of dynamic operation.

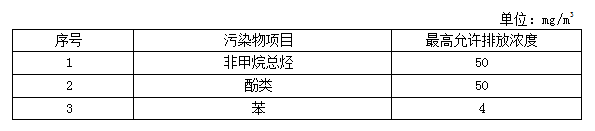

6, the indicators after treatment requirements

According to the location of the enterprise and the requirements of the local environmental protection administrative department, the process exhaust gas is implemented in Hebei Province Local Standard "Discharge Standard of Volatile Organic Compounds of Industrial Enterprises" DB13 / 2322-2016 Organic Pollutants and Emission Limit in Waste Gas and Coking Chemical Industry Pollution Emission standards "(GB16171-2012) organic pollutants in the exhaust emissions and emission limits, the main emission targets in the table below:

Table 1-1 Local standard of Hebei Province "Discharge Standard of Volatile Organic Compounds in Industrial Enterprises" DB13 / 2322-2016

版权所有·北京天中方环保科技有限公司 京ICP备14001063号-2